Do-it-yourself cold smoked smokehouse: video, photo - instructions for self-production

A great way to create quality products on your property for the whole family is the cold smoked smokehouse. It can be used to process fish and all types of meat. Smoking allows you to keep food for a long time. To make such a unit, let's get acquainted with the technology of its manufacture and find out how to properly design a cold-smoked smokehouse with our own hands. Videos, photos and drawings will help with its construction. Moreover, it does not need a lot of space to place it.

DIY equipment

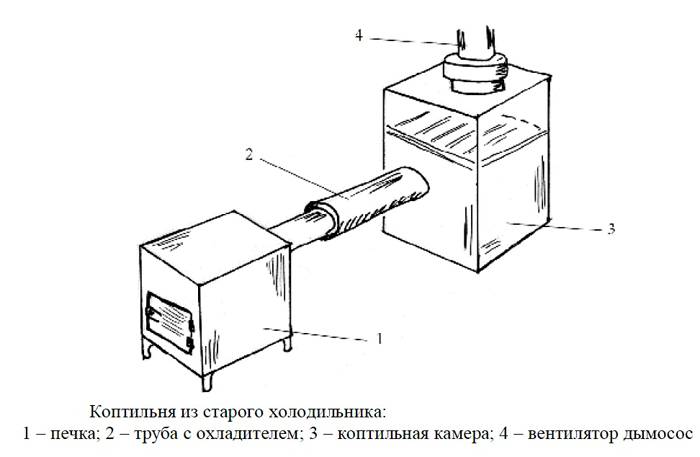

The characteristic of a homemade smoking device is its low cost. You can build it from a variety of materials - old barrels, steel sheets, pieces - all of these will fit for a useful device.

Helpful information! Since fat is released from various products when smoking, a special tray is placed behind the grate. In this case, gaps should remain between the container and the walls. It is also worth placing a moist matter above the firebox, through which the combustion products will leave, but pollutants will not penetrate.

How to assemble a stainless steel smokehouse

A similar cold-smoked smokehouse with your own hands is often made from stainless steel. The insides of such equipment resemble a box with grates that are installed on welded corners. This is a portable version that looks like a suitcase. For the marching structure, sawdust and small firewood are used.

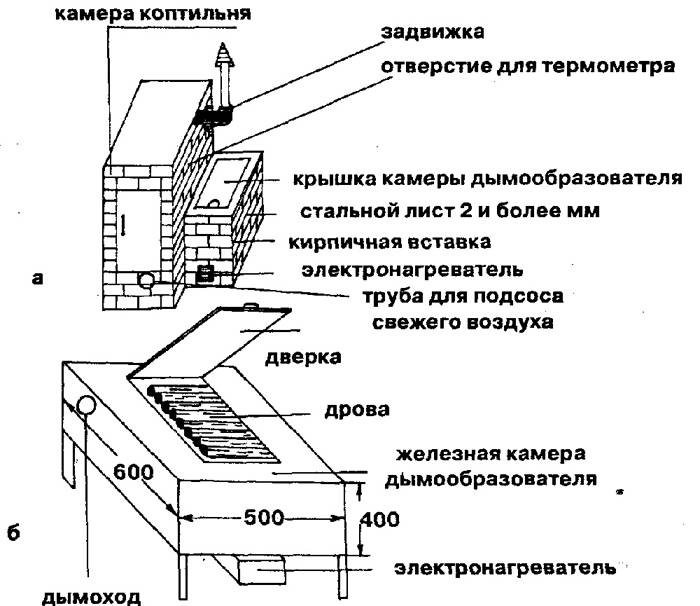

Brick construction

The brick smoker is a stationary option. To build it, you must first select a suitable place on the site. Before work, a drawing of the product is made with markings of all sizes. Be sure to consider the placement of the smoke source. In some cases, a stove stove is used for firewood. In this case, the oven with the smokehouse chamber is connected using a pipe.

Gas cylinder model

From an unnecessary and empty container, you can build a good cold-smoked smokehouse with your own hands. Videos, photos and drawings of individual projects will allow you to choose an option for your site. If you have an old gas cylinder, you can do a useful thing by following these points:

- the remaining gasoline must be drained from the cylinder;

- remove the tap and pour water into the hole. Only then can the container be cut;

- you need a large door to load food. At first, the cuts are not made completely so that the door does not boil;

- clean out the places for the hinges that need to be welded to the door and the main part of the cylinder;

- a strip is cut off at the bottom, and then the bottom;

- the firebox must be made of iron sheets. The firebox is welded to the cylinder.

Before carrying out the first smoking, you need to fire the structure with wood.

Helpful information! Remember that leftover gasoline and its vapors are very dangerous.

How cold smoking is done at home: the design of a smokehouse

Drawings of a homemade cold-smoked smokehouse will help to build the correct installation. You can mount the unit with your own hands if you know its structural features and the principle of operation.

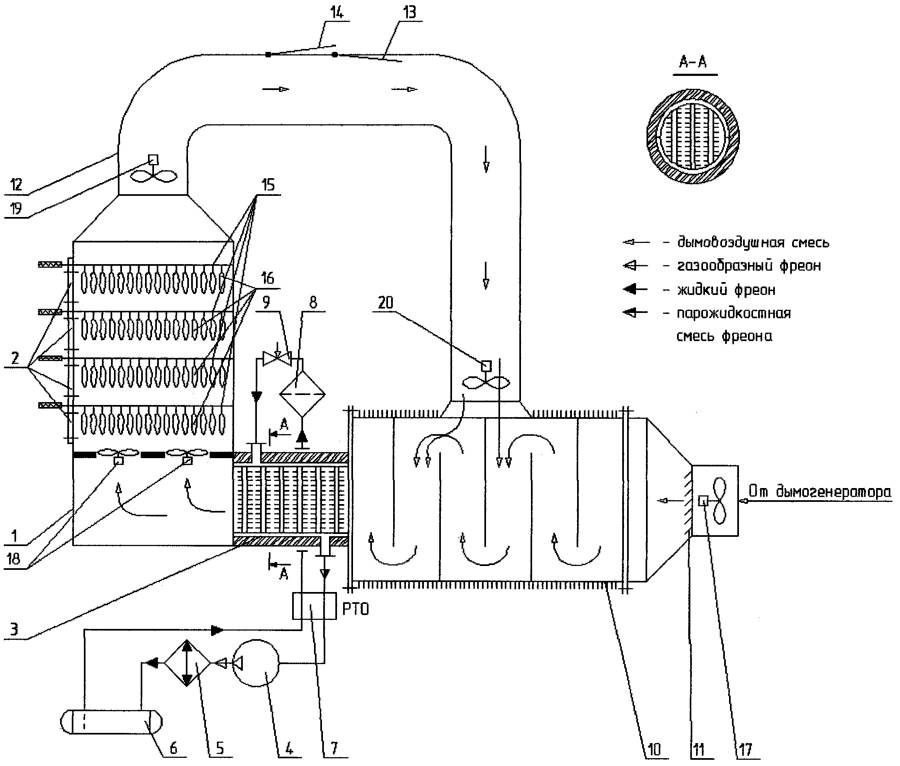

The principle of such smoking is that the product is blown with smoke, which has a temperature of no more than 30 degrees. The smoke is cooled in a pipe that connects the combustion chamber with the smokehouse tank. Products in this design can be smoked for a couple of days.

The smoking equipment consists of the following components:

- partitions;

- tongue-and-groove covers;

- chimney;

- a chamber consisting of a barrel-shaped reservoir;

- knees;

- chimney structure.

The product includes two cameras. In the first, firewood is burned, and in the other, meat and other products are placed. In the installation, the distance between the tanks must be longer than in the hot smoker, since the smoke must cool down. There is another pipe in the combustion chamber that removes excess smoke.

The versatile equipment is a cold-smoked smokehouse with your own hands. Videos, photos of individual models allow you to see their device. You can smoke not only meat products or fish, but some vegetables and fruits.

Helpful information! The best option for a private house is a brick device. Before work, you need to calculate the chimney line.

How to make a cold smoked smokehouse with your own hands: stages of work

There are many methods for making a cold smoked smokehouse. We suggest the following method. The structure looks like a structure on supports. On the front part, there is a door through which products are served. A door is located below, where a container for collecting fat is installed.

For mounting, you will need a steel sheet 1 mm thick, lining, rail and timber.

Table 1. Creating a cold smoked smokehouse with your own hands

| Image | Stages of work |

|---|---|

| We construct a frame from a bar, which should be equal to the dimensions of the smoking chamber. |

| With the help of the lining, we sheathe the floor, the walls, the roof of the frame structure. In this case, you need to tightly fit the boards. Reinforce the walls with spacers just in case. |

| A hole is cut out at the bottom where the smoke will pass. It should be equal to the cross-section of the chimney elbow. And in the roof, make a hole for the smoke outlet. Planks are also fixed there, where the hooks will be hung. |

| With the help of boards, a door is made, and then hung on the hinges. The door is located under the roof of the structure. |

| A hole is made at the bottom where a reservoir will be mounted for the accumulation of fat released from products. Angles are attached inside the chamber, with the help of which the tray will move. |

| A tray is formed from steel, to which a door with a handle is welded. |

| As a firebox, you can use a stove, like a stove. If there is no suitable equipment, then you can make a base from a pipe or cylinder. The legs need to be welded to the body. The stove should be located below the smoking chamber. A pipe is welded to the back of the stove, and a pipe adapter is placed in the hole. For the firebox, a door is cut out, in which there should be a hole to create better draft. |

| An angle adapter is attached to the opening in the smoking chamber. | |

| The tank of the smokehouse and the firebox are connected by means of pipes. Remember to make the chimney with a certain slope. This bevel will increase traction in the smoking container. After assembly, the device needs to be checked. It is better to use raw wood firewood for smoking. You can use wet wood chips for DIY smoking. |

| Here's what happens in the end |

Helpful information! If smoking is done correctly, the products will have excellent keeping quality and excellent taste. Such products do not have harmful properties, especially when made at home.

- do not forget to monitor the temperature indicators inside the chamber;

- smoke in dry weather, it is important that there is no precipitation;

- do not open the chamber door too often, as this will delay the process;

- you can add juniper, cherry or grapes for the best flavor;

- to make the taste of the product pleasant, take care of uniform heating and fumigation of the product;

- do not use coniferous trees, as they will spoil the taste of the food.

If the process of building a smokehouse is too complicated for you, you can purchase a ready-made version. When doing this, pay attention to the material of the product. It should not contain harmful impurities. The thickness of the structure matters. If the material is too thin, the product will quickly rust. Special sensors will allow you to regulate temperature conditions.

![]()

Now you know what a cold smoked smokehouse is. If you follow simple recommendations, you can make a high-quality home-made unit without much hassle and unnecessary financial costs.